Material: SUS304 / SUS316 food grade

Capacity: 24000BPH for 500ml

Min Order: 1 set

Siemens PLC & Touch screen

Specially designed according to customer's bottles and caps.

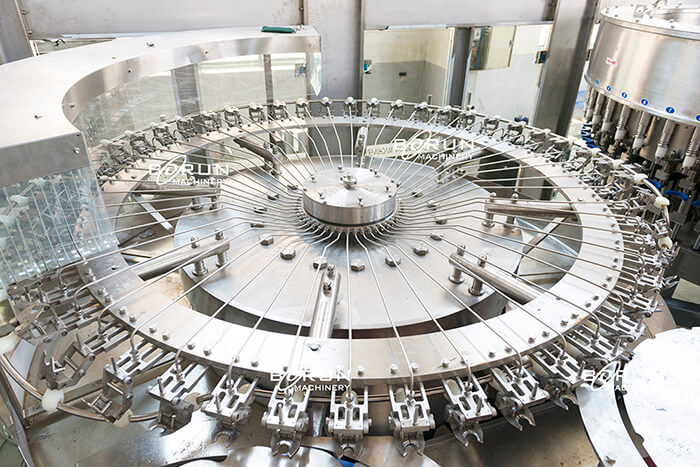

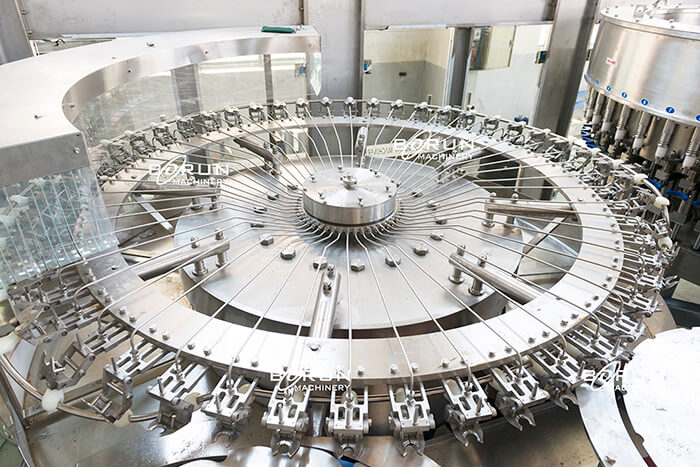

This CGF50-50-15-15 pet bottled water filling machine is mainly used for non carbonated beverage drinks such as mineral water, pure water, non-gas water and so on. It is 4 in 1 monoblock composed of washing, filling, capping in one unit. The water filling machine design could shorten the time for the drink material contact with outside, increase the sanitation condition throught economy benefit.

The machine adopts advanced Simens PLC and touch screen to ensure stable running. The empty bottles adopt air conveyor transfering to the 3 in 1 machine, and output bottles adopt flat conveyor with inverter to make sure the water filling machine speed adjustable.

Features:

* Easy operation and maintenance;

* Advanced Siemens PLC and touch screen;

* Gravity Filling with high capacity;

* Italy technology capping more precision.

* Belt type cap uploader with new tehnolgy avoid cap blocking.

Rinsing heads

Water Filling heads

Capping heads

Technical Parameters:

Model | CGF50-50-15 | |

Rising heads | 50 | |

Filling heads | 50 | |

Capping heads | 15 | |

Capacity based on 500ml PET bottle | 24000BPH | |

Suitable bottle shape | PET bottles with different volume and shapes | |

Suitable bottle diameter(mm) | Φ50-110 | |

Suitable bottle height | 160-310mm | |

Compressed air pressure | 0.3-0.7MPa | |

Washing water pressure | >0.06MPa,≤0.2MPa | |

Motor power (KW) | 7.5 | |

Dimensions(mm) | 4720*3550*2750 | |

Weight (KG) | 8000 | |

Maintenance of automatic water filling machine:

Every shift of production shall carry out an overall clean of machine and the inspection of the fixing parts to ensure no looseness either at beginning or at the end.

If the meshing of gears is not satisfactory the remedy work shall be carried out and lubricate the gears with grease at last.

When the seasonal production is finished or any temporal stop of production happens in a year, an overhaul shall be carried out and the wearing-and-tearing parts should be replaced ensuring the satisfactory production of next term.

Notes:

1) When cleaning, forbid any water spray over rotating or electrical parts;

2) Bottles and caps shall accord with technical requirement and any discord ones shall be forbidden to be applied lest causing mechanical failure;

3) Each interconnecting of drive-and-driven pairs shall be precisely adjusted lest any bottle-blocking will occur;

4) Regular inspection of lubrication spots and ensuring satisfactory lubrication.