Material: SUS304,

Capacity: 1400BPH for 5L bottle.

Washing, Filling, Capping 3 In 1 Machine controlled by PLC

Min Order: 1 set

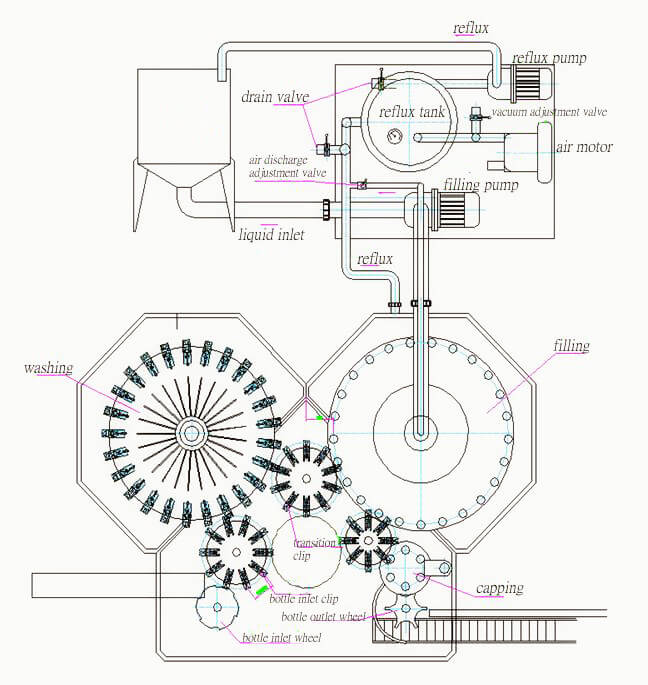

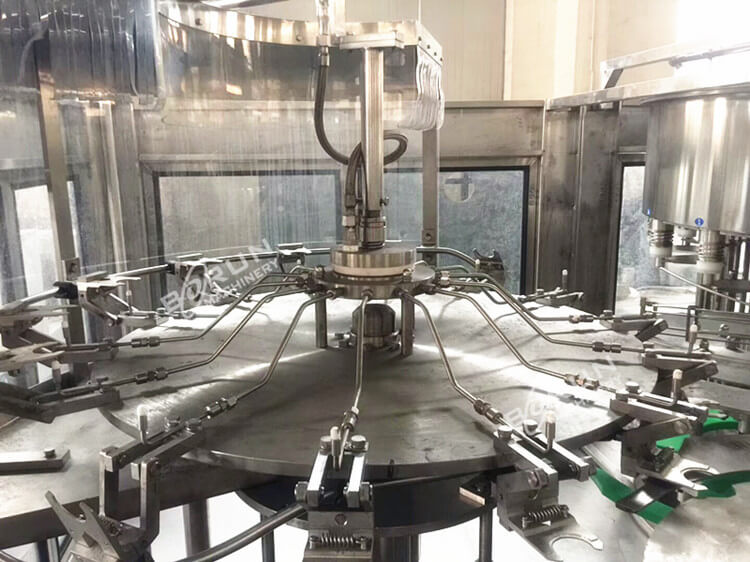

The rotary type 5L water filling machinery adopts advanced technique and filling technology. The machine starts from transmit empty plastic bottle and separating bottles by star wheel through the wind way,the star wheel bottle-clip clamps the bottle and convert the empty bottle to bottle washing machine, the bottle-clip of the bottle washing machine clamps bottleneck ,turn over along the lead rail of the bottle washing machine and then wash the bottle.The cleaned filling bottle are passed to the filling machine through the transition star wheel,the clamp bottle block clamps the bottleneck,,the filling valve fall down along the lead rail of the cam,bottleneck faces the volve port of filling valve ,then open the filling valve according to the program so as to fill. After filling is finished,pass the bottle to capping machine through small transition star wheel,the capping clipping plate claps which clamping the bottleneck,at last transmit the beverage bottle which is capped to the conveyer belt. It's an ideal filling equipment for big bottle water makers.

Features:

1. Simple operation and easy maintenance;

2. Stable running and energy saving;

3. Advanced technique with reliable performance;

4. high automatization and sanitation.

Technical Parameters:

Model | CGF12-12-4 | CGF15-15-5 | CGF25-25-6 |

Capacity(BPH) | 1400-1500 | 1500-2000 | 3000-3500 |

Total power(KW) | 2.2 | 3 | 8 |

Dimension(mm) | 3000*2000*2500 | 3350*2500*2500 | 5380*3950*2900 |

Weight (KG) | 4000 | 4500 | 6000 |

Spare parts list:

No. | Name | Specification | Quantity |

1 | Liquid input slide lock ring | Φ104×Φ8 | 4 |

2 | Reflux slide lock ring | Φ70×Φ5.3 | 4 |

3 | Filling Valve close lock ring | Φ46.2×3 | 25 |

4 | Filling valve core slide lock ring | Φ40.2×5 | 25 |

5 | Filling valve mouth pad | Φ57×15 | 25 |